Hat Channel Profile Roll Kugadzira Machine

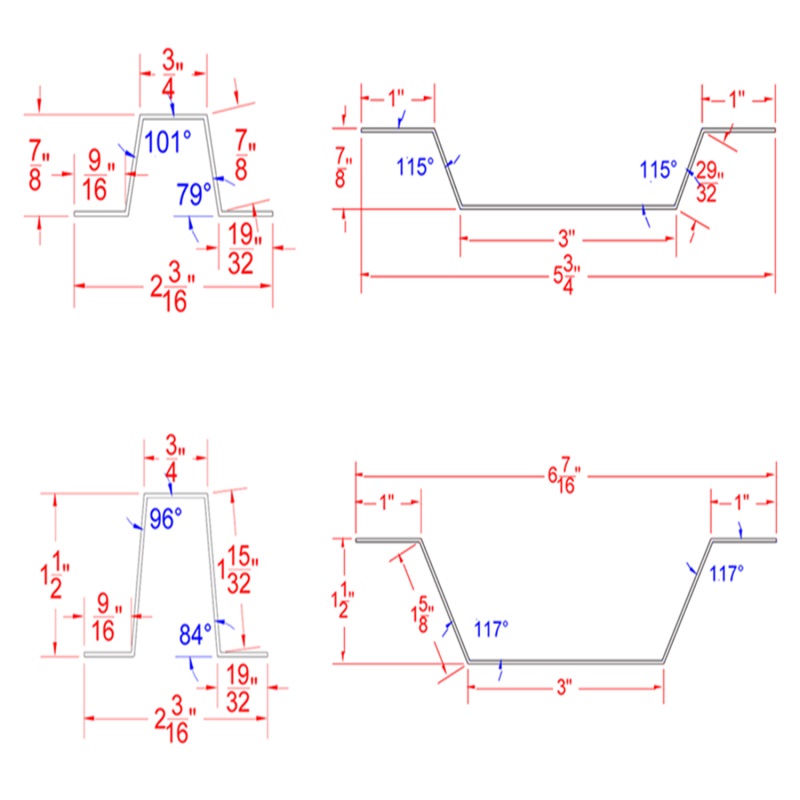

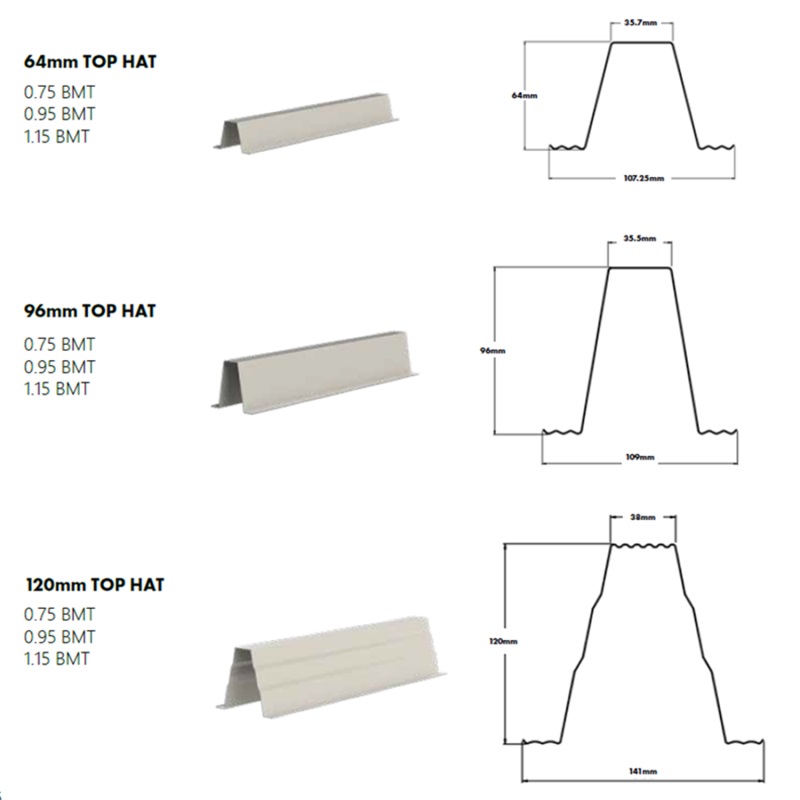

Hat chiteshi ndeimwe imwe mhando yesimbi padenga framing system, iyo inogona zvakare kushandiswa seye purlin panodiwa yakaderera profiles, kana iyo yekuvhara system inoda padhuze purlin spacing nekudaro kuita yakajairwa "Z" kana "C" purlins inodhura zvakanyanya.

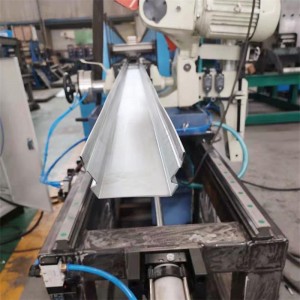

Yedu hat profile roll yekugadzira muchina ndeyekugadzira heti nzira, iyo inoshanda zvakanyanya musimbi / simbi padenga rekuvaka maindasitiri.

Nyora meseji yako pano uye titumire kwatiri