High Frequency Tube Welding Mill Line

Product Description

High frequency straight seam welded pombi yekugadzira mutsara inonyanya kushandiswa kugadzira emagetsi welded simbi mapaipi ane φ60.~φ219mm uye kukora kwemadziro kwe2.0~6.0mm, uye inokwanisawo kugadzira mapaipi akaenzana neane rectangular uye mapaipi akasarudzika asingadarike huwandu hwemapombi akatenderera.API 5L machubhu anogona kugadzirwa gare garenekuwedzera midziyo inodiwa.Mutsara wekugadzira wakagadzirwa uye unogadzirwa pahwaro hwekugaya uye kutora midziyo yakafanana kumba nekune dzimwe nyika, ichibatanidza nemamiriro enyika yangu, neushingi kuvandudza, uye kuteerera kumafungiro evashandisi zvakanyanya.Iyo michina ine hupfumi, yakavimbika uye yakagadzikana.

Basic Parameter

| Yakaderera kabhoni simbi uye yakaderera alloy simbi | σB≤520mpa σS≤345mpa | |

| Simbi Coil | dhayamita yemukati | φ650-φ710mm (kutsanangurwa) |

| Kunze dhayamita | φ1100-φ2000mm | |

| Roll uremu | ≤15 matani | |

| Strip width | 190-690mm | |

| Magetsi akaiswa simba | anenge 1200KVA | |

| Yakadzvanywa mweya simba | 2m3/min 4-7Kg/cm2 | |

| Inotonhorera kugona | 50 matani / awa | |

Production Process

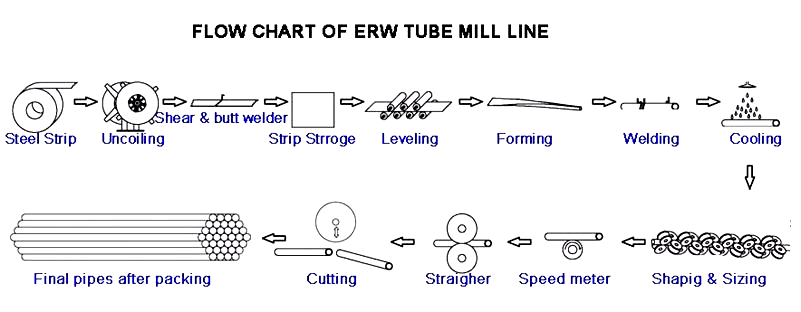

Kusunungura → musoro wakatwasuka, pinch kuenzera → kugera butt welding → looper → kuumba, high frequency welding, deburing, on-line zingi replenishment, kutonhora, saizi, kutwasanuka → kubhururuka masaha saizi → kuongorora nekuunganidza → kurongedza →Kuyera→Kumaka→Kuchengeta

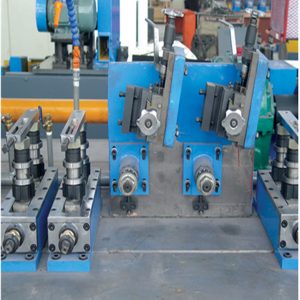

Welding Tube Mill linekuumbwa uye mikuru paramita yemuchina wega wega

1.Kudyisa Trolley

| Usage | Inoshandiswa kugashira coil ye strip, kuendesa kune decoiler, uye kusimudza coil coil kusvika pakati pemusoro wecoil. | ||

| Chimiro | Iyo inoumbwa neyezvinhu rack, yekufambisa michina, silinda yemafuta, njanji, nezvimwe. | ||

| Capacity | ≤15T | Mira | Hydraulic |

| Moving Mode | Motokari ine cycloid reducer drive | ||

2.Uncoiler

| Usage | Zvekurembera uye kutsigira strip coils kupa mbishi zvinhu zvekugadzira mitsetse | |||

| Capacity | ≤15T | Braking nzira | Pneumatic brake, solenoid valve control | |

| Uncoiler | Hydraulic kuwedzera uye kuderera | Single cone hydraulic kuwedzera uye kuderera | ||

3.Straightening machine

| Usage | Inoshandiswa pamwe chete neyeuncoiler, musoro wesimbi unodhonzwa kubva kune uncoiler uye unotumirwa kumuchina wepinch wekuyera chiyero. | ||

| Chimiro | Dzvanya roller mudziyo, foshoro musoro mudziyo, wakatwasuka musoro mudziyo | ||

| Upamhi | 190-690mm | Diameter | φ1100-φ2000mm |

4.Pinch kudya uye Leveling Machine

| Usage | Kuenzanisa tambo yesimbi kubva pakusunungura uye muchina wekutwasanudza kumusoro nemuswe uye kuendesa tambo yesimbi kumuchina wekugera butt welding. | ||

| Chimiro | Kuumbwa kwepinch roller, leveling roller uye mudziyo wekutumira | ||

| Upamhi | 190-690mm | Diameter | φ1100-φ2000mm |

Tube Mill Mutsetse weWorkpiece